Today's HoursMonday 8:00AM - 5:00PM

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | Closed |

| Sunday | Closed |

New Equipment

Challenger® RoGator Dry RG900C

-

ID # 26649757

- Back ID:26649757

- Book a Demo

- Get Directions

|

Highlights

|

|

Competitors wish they had the industry-leading accuracy of the RoGator dry application system. With AirMax® Precision R1/R2, UltraSpread™ motors, and TurnLogic™ technology, you don’t have to settle for missed targets. Put the right amount of product in the right place with the right machine—RoGator. |

|

Single-Bin and Twin-Bin Variants

Provide multi-season capabilities and increased flexibility. With the R2, a single lever changes the bin configuration from 50/50 to 60/40 to suit the field’s specific capacity needs. Samples can be taken from the front platform of either configuration to check for density. With the R2, samples can also be taken from the rear platform.

Booms

70 ft. long and made of six 304 stainless steel tubes, leveraging a suspension system of hydraulic cylinders and accumulators that increases stability, even coverage and spread pattern accuracy. |

|

UltraSpread™

Radial piston hydraulic motors provide low speed and high torque to maintain consistent motion under the load of product in the box.

|

|

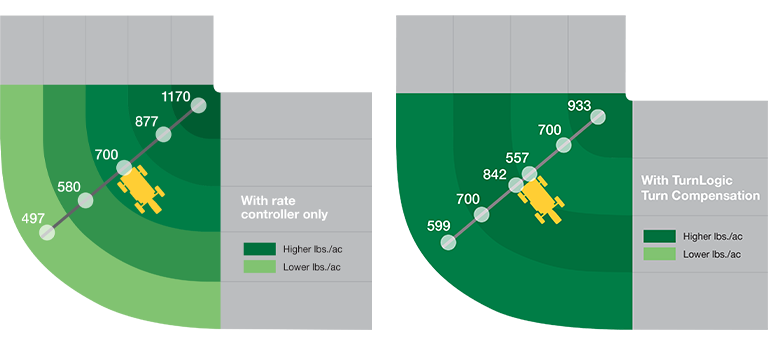

TurnLogic™ Automatically adjusts distribution rates to ensure even coverage during cornering, helping maximize yields while improving soil and plant health.

|

|

Drop Hoses Drop hoses can be purchased through AGCO Parts to place late season nitrogen or cover crops between the rows and below the crop canopy, increasing effectiveness of the application and preventing fertilizer or seed from becoming trapped in the whorl of the plant. |

|

Recon SpreadSense®

Acoustic sensor provides real-time flow detection through a pneumatic spreader, displaying blockage information in the cab. |

|

Four MultApplier Ready Models

Featuring wide, tapered sides for quick filling and a spread width of up to 120 ft. (36 m.). In just a couple hours, the LiquidLogic ® system can be easily changed out for a spinner, providing year-round usage and improved ROI. L4500 Edge This family of spreaders includes many new features to keep this box running accurately for many years, including:

|

|

Control has never been so comfortable Every inch of the RoGator® cab has been designed to maximize your riding experience—and your efficiency.

|

|

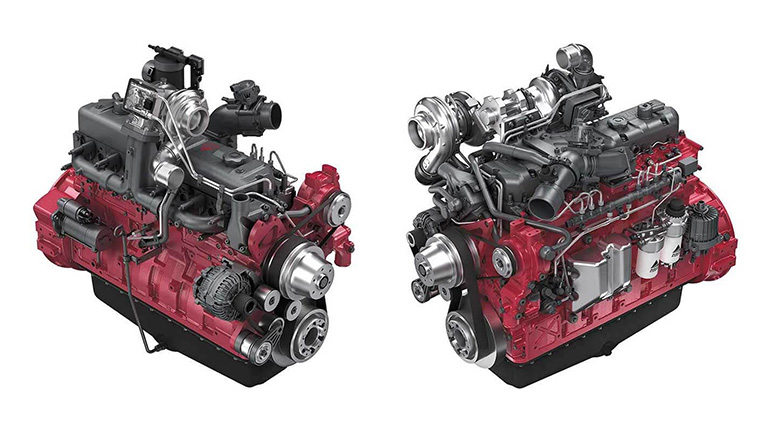

Power meets performance

The horsepower, torque and fuel economy to handle any terrain with ease—all while meeting emission compliance regulations.

Choose the ProTechi package with AgControl that offers LiquidLogic or SpreadLogic standard. ProTechi is easy to use with rate and section control, integrating seamlessly between software, pump, plumbing system or dry conveyor and fan speed, including all chassis functions Better traction, better results Ride confidently with SmartDriveTM technology, featuring continuous and independent control of each wheel for maximum traction. It automatically sends more power to the gripping wheel and ensures it gets the torque it needs, all while managing the slipping wheels—without any user input.

|

|

Fewer tracks, more benefits

Capabilities: Drive in a standard position with 2WS or minimize turn radius with either the 4WS or 4WS Auto. Use Crab steering to avoid field obstacles while maintaining precise even coverage. Reduce Compaction: Initial tire paths compact soil by 80%, making it essential to reuse them whenever possible. GatorTrak 4-wheel steer maintains rear wheels in front wheel paths, reducing compaction in end rows and headlands. Minimizes Crop Damage: A tight 16 ft. turning radius means far fewer rows are crossed and compaction is reduced, significantly reducing crop damage and enhancing yields. Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year. Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year |

|

Your operation’s competitive advantage

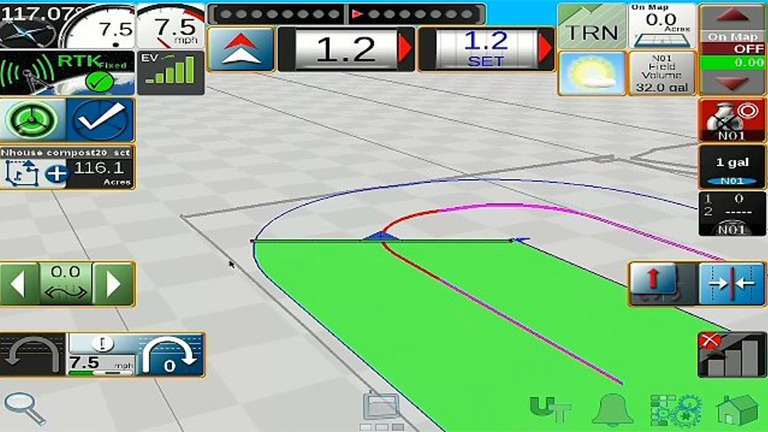

Find the latest technology inside every RoGator®. The intuitive, fully integrated AccuTerminal® gives you full machine control—from the chassis and steering to data management and system functionality—all while decluttering your space with a single screen.

|

|

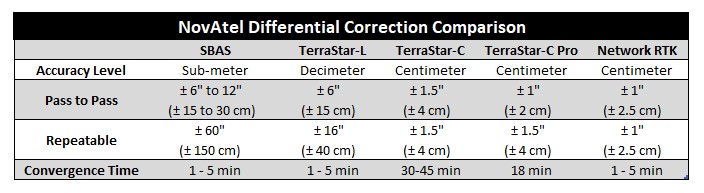

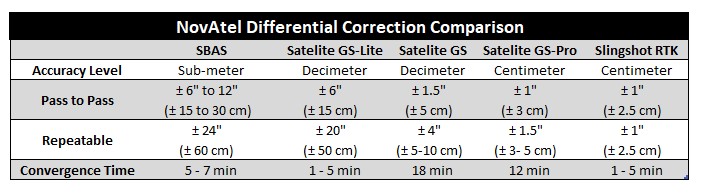

Standard NovAtel 7 Receiver A rugged, self-contained GNSS receiver and antenna with GPS and SBAS support. Base GPS option is SBAS but can be upgraded for higher accuracy levels. |

|

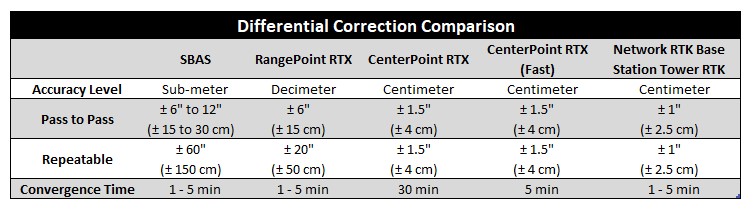

Optional Trimble AG-482 Solution A high-performance, dual-frequency GPS and GLONASS smart antenna receiver for very high levels of accuracy and performance. Base correction source is SBAS but can be upgraded for higher accuracy levels. (Show Trible chart) |

|

Take your technology to the next level

If you’re looking for the ultimate in cab and machine technology, look no further than the ProTech+ package. Viper ® 4+: Offering the ultimate combination of operating power and program capabilities:

|

|

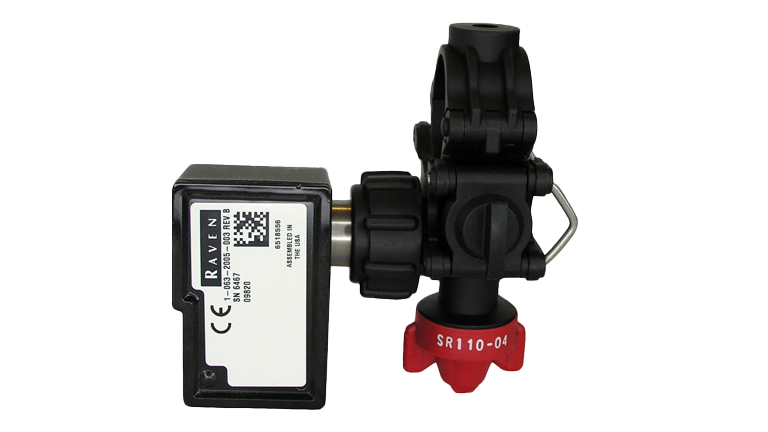

Hawkeye Nozzle Control System Pressure-based system for precise application available through parts. Each nozzle is controlled by an individual pulsing valve to give a consistent spray pattern as speed and conditions change.

|

|

RS1 Guidance Technology Fully scalable steering solution that combines Slingshot, GPS and auto steer into one intuitive, easy-to-use unit with incredible accuracy at both high and low speeds |

|

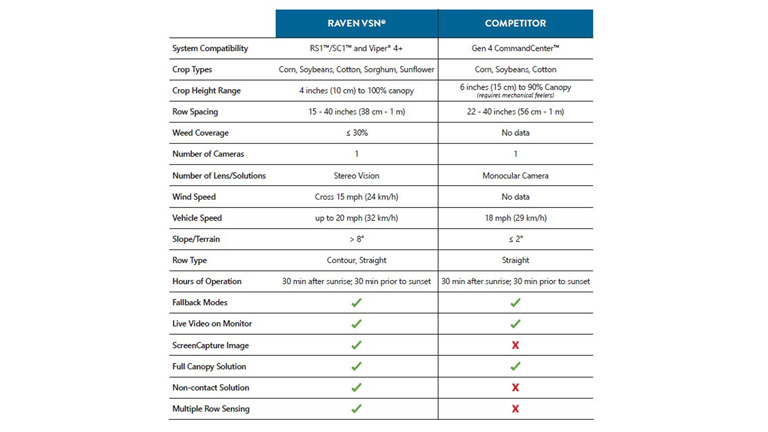

VSN Leverages a non-contact stereo vision camera to navigate crop rows, allowing you to focus on all other aspects of effective application control. The system helps to minimize crop damage, cover more acres in less time and provide easier machine operations. (VSN Comparison Chart)

|

|

VSN Full Canopy When crops are too tall to effectively see the row, the Raven VSN Full Canopy solution compliments the VSN system with a non-contact radar sensor that detects stalked crops, such as corn, to keep the machine in between rows. Available through AGCO Parts.

|

|

Raven AutoTurn Included with the purchase of VSN, automatically performs headland turns without the operator’s input, allowing them to prepare for the next pass |

|

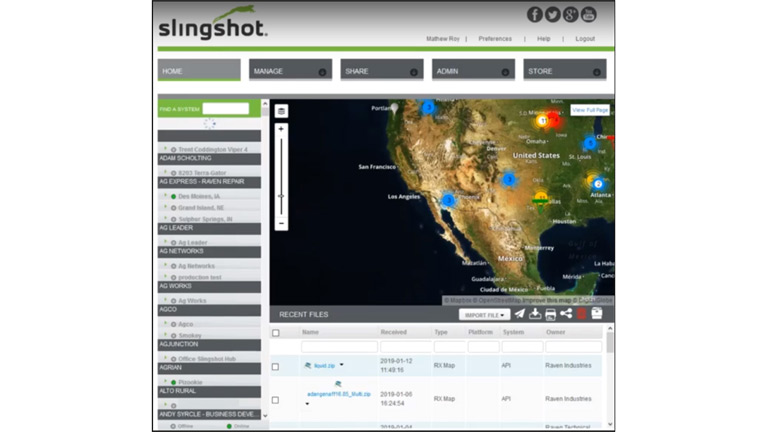

Slingshot Suite of connected hardware, software and logistical services that optimize planning, executing and recording field applications. This system delivers high levels of connectivity to RTK correction signals, online services, sophisticated data management capabilities and live in-field support and service. |

|

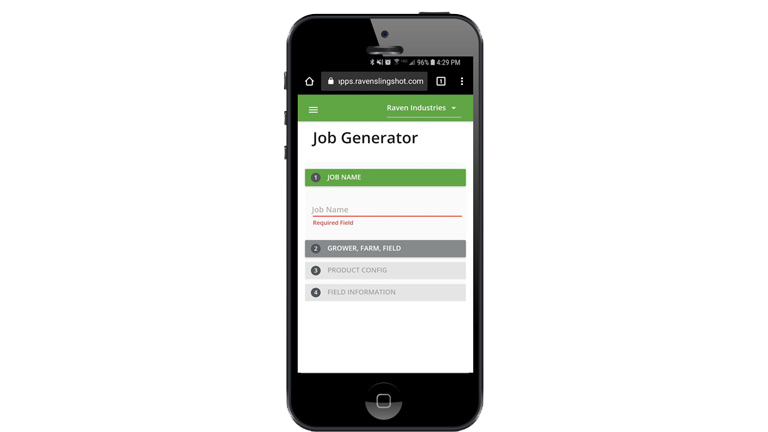

Job Generator

Fast and simple way to set up nearly all parameters of an operation ahead of time and send it out to the machine. |

|

job Sync Harnesses Slingshot to allow multiple machines to collaborate on a job simultaneously or days apart—a powerful tool that practically eliminates the potential for overlap or misapplication between multiple machines in the same field. |

|

AgSync Ground Flexible and scalable tool that leverages Slingshot’s data transfer power to streamline otherwise complex tasks, such as work order management, dispatch and asset control, reports and notifications, and filing data management. Weather Station Data: View the latest weather information and record data as a snapshot in time to use it for documentation of the application. |

|

Data management done right Agro Link relieves you of the data management burden by collecting, integrating and storing agronomic files—so you can focus on more important tasks.

|

|

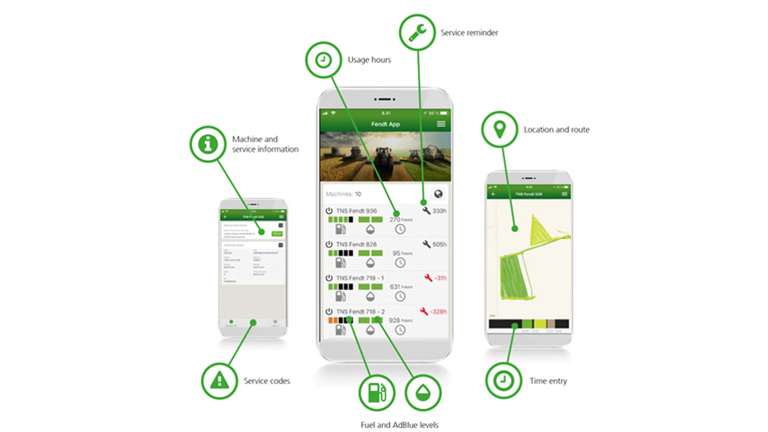

Connected performance perfected Take the guesswork out of machine optimization with AGCO Connect. Track individual and fleet performance and know where, how and when you can make the most of your machines.

|