Today's HoursThursday 8:00AM - 5:00PM

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | Closed |

| Sunday | Closed |

New Equipment

Challenger® ROGATOR® LIQUID RG1300C

-

ID # 26649756

- Back ID:26649756

- Book a Demo

- Get Directions

|

Highlights

|

|

Don’t spray harder—spray smarter with RoGator’s liquid application system. Featuring LiquidLogic®, AWD SmartDriveTM and GatorTrakTM technology, it’s specifically designed to give you full control to deliver a more precise, efficient and effective application every time. Only on a RoGator. |

|

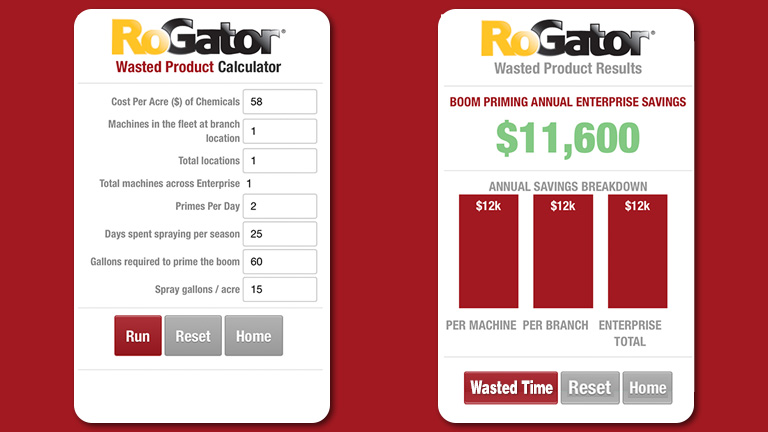

LiquidLogic® Save valuable inputs, time and money Unlike conventional spray systems, LiquidLogic® recirculation primes the boom in 45 seconds flat—saving you $232 per prime. And that’s not the only benefit.

Savings Per Season

Purdue University’s agronomy department released estimates that chemical costs for corn are around $58 per acre. With about 4 acres of wasted product every time a prime is performed, this amounts to $11,600 of wasted product per season when priming two times per day. Purdue University’s agronomy department released estimates that chemical costs for corn are around $58 per acre. With about 4 acres of wasted product every time a prime is performed, this amounts to $11,600 of wasted product per season when priming two times per day. E-Stop™ Control Control up to 36 boom sections using e-stops and reduce overlap and wasted product while eliminating damage to management zones by utilizing durable electronic ball valves for instantaneous on/off section spray control. OptiMotion™ Auto-Agitation Automatically adjusts as the tank volume changes, freeing you to focus on application or refill rather than valve adjustments. Boom Clean Out Available on RoGator for 21 years, system effectively pushes product out of the boom plumbing to ensure clean lines and reduce contamination and crop damage—saving you up to $2,500 per spraying season. OptiLoad™ Reload System Transforms time-consuming rinsing procedures into a simple task accomplished inside the cab and at the reload station to ensure that every area of the machine is rinsed. RoGator’s reload area uses sweeping elbows and “Y” fittings in place of hard 90° and “T” fittings, reducing product build up. The continuous recirculating boom plumbing eliminates dead-end spots in which chemicals can get trapped and removes the need to pull end caps. A recent Purdue study determined that the FlowLogic recirculation boom plumbing can be rinsed to effectively remove water-soluble contaminants by 99.6% or greater with a triple rinse. ClearFlow™ Product Recovery System Manage rain, wind and other conditions by flushing unused product from the plumbing back into the tank prior to rinsing, where it can be re-agitated or off-loaded, minimizing waste and contamination.

Direct Injection

Whether using it for adjuvants or chemicals, this system allows you to inject variable-rate product into the system before the booms, all while reducing your risk of cleanout contamination. The system leverages a dual high-volume pump (5-200 oz. per min pump) with dual 40-gallon tanks mounted on opposite sides to keep the machine balanced with ground fill and rinse at the reload area. Eliminate Waste Exclusive FlowLogicTM technology maintains circulation and provides immediate flow throughout the boom, eliminating clogging, settling, and wasteful stationary spraying while always maintaining an optimal mixture. | ||||||||||||||||||||||||

|

Booms

A boom for every operator Whether you’re trying to apply the highest volume possible, broadcasting over solid seeded crops or applying between rows, RoGator® has the boom for you. Steel Booms: 90-, 100- and 120-ft. lengths with 10-, 15- and 20-in. nozzle spacing available. Optional Aluminum Boom: 132-ft. length, and 5% lighter than steel for improved efficiency, less compaction, and nozzle and plumbing protection contained inside the A-frame structure.

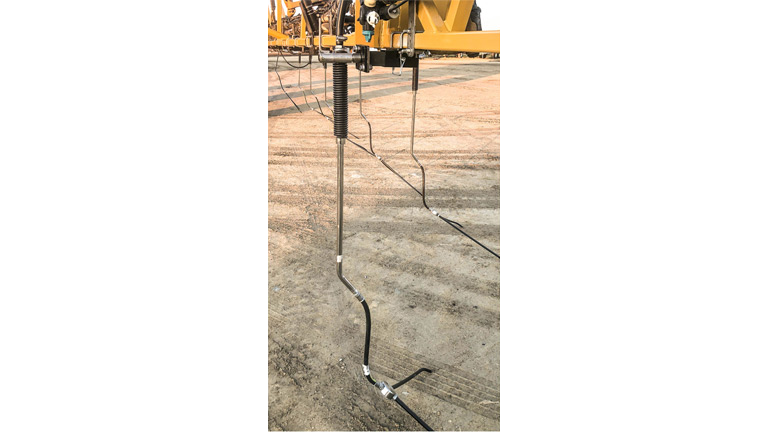

EZ Drops

Crop-guided, lightweight system for late-season nitrogen applications delivering nutrients on target to the base of the plant. Heavy-duty stainless steel breakaway springs and high-wear tips ensure durability, and the system can be folded from the cab for more convenience.

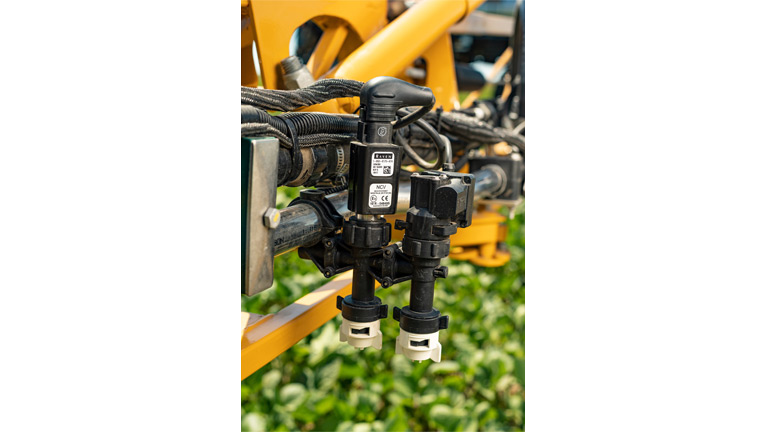

Hawkeye® Nozzle Control

A pressure-based system for precise application available through parts. Pair this with the E-Stop Control system to increase the system’s flow capabilities to open up a wide rate range. Various modes that increase the versatility of the system include:

| ||||||||||||||||||||||||

|

Control has never been so comfortable

Every inch of the RoGator® cab has been designed to maximize your riding experience—and your efficiency.

| ||||||||||||||||||||||||

|

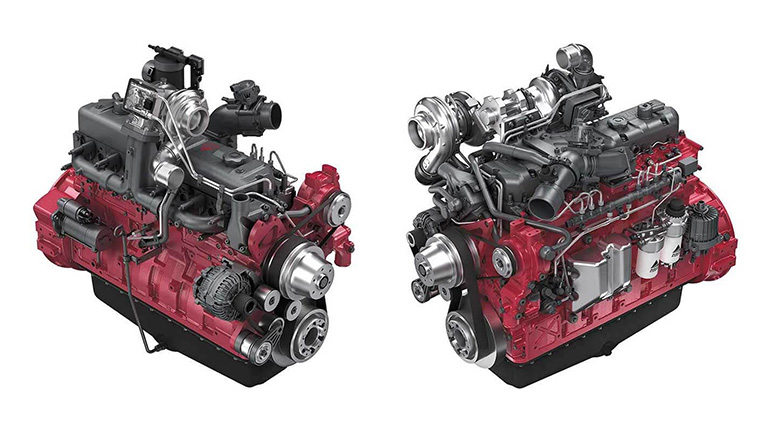

Power meets performance

The horsepower, torque and fuel economy to handle any terrain with ease—all while meeting emission compliance regulations.

| ||||||||||||||||||||||||

|

Fewer tracks, more benefits

Capabilities: Drive in a standard position with 2WS or minimize turn radius with either the 4WS or 4WS Auto. Use Crab steering to avoid field obstacles while maintaining precise even coverage. Reduce Compaction: Initial tire paths compact soil by 80%, making it essential to reuse them whenever possible. GatorTrak 4-wheel steer maintains rear wheels in front wheel paths, reducing compaction in end rows and headlands. Minimizes Crop Damage: A tight 16 ft. turning radius means far fewer rows are crossed and compaction is reduced, significantly reducing crop damage and enhancing yields. Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year. Save Time and Improve ROI: For those without headlands, a standard 2-wheel steer machine may require a three-point turn after each pass. If each turn takes an average of 18 seconds, and an average field is 80 acres, with GatorTrak 4-wheel steering you could cover an additional 100 acres per day or 4,500 acres per year | ||||||||||||||||||||||||

|

Your operation’s competitive advantage

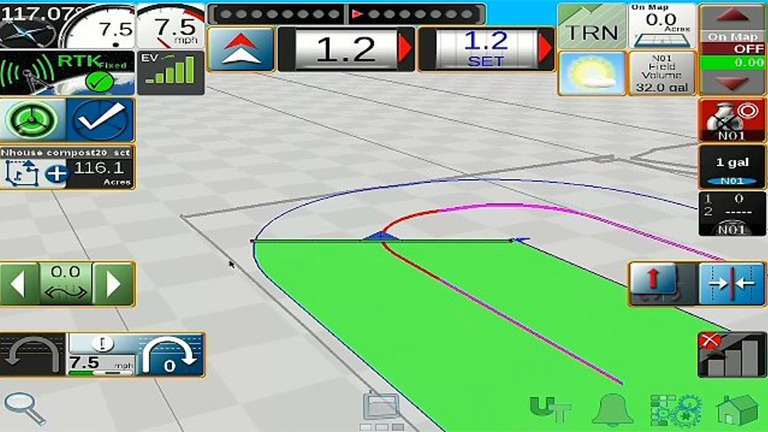

Find the latest technology inside every RoGator®. The intuitive, fully integrated AccuTerminal® gives you full machine control—from the chassis and steering to data management and system functionality—all while decluttering your space with a single screen.

| ||||||||||||||||||||||||

|

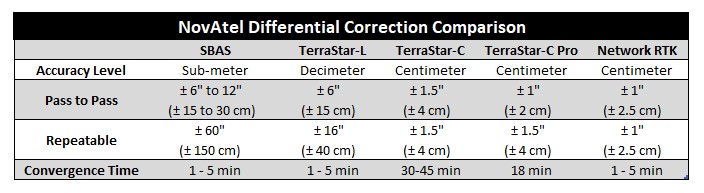

Standard NovAtel 7 Receiver A rugged, self-contained GNSS receiver and antenna with GPS and SBAS support. Base GPS option is SBAS but can be upgraded for higher accuracy levels. | ||||||||||||||||||||||||

|

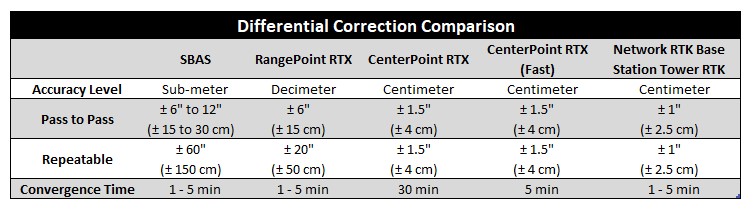

Optional Trimble AG-482 Solution A high-performance, dual-frequency GPS and GLONASS smart antenna receiver for very high levels of accuracy and performance. Base correction source is SBAS but can be upgraded for higher accuracy levels. (Show Trible chart) | ||||||||||||||||||||||||

|

Take your technology to the next level

If you’re looking for the ultimate in cab and machine technology, look no further than the ProTech+ package. Viper ® 4+: Offering the ultimate combination of operating power and program capabilities:

| ||||||||||||||||||||||||

|

Hawkeye Nozzle Control System Pressure-based system for precise application available through parts. Each nozzle is controlled by an individual pulsing valve to give a consistent spray pattern as speed and conditions change.

| ||||||||||||||||||||||||

|

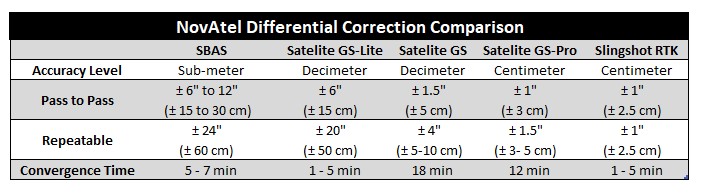

RS1 Guidance Technology Fully scalable steering solution that combines Slingshot, GPS and auto steer into one intuitive, easy-to-use unit with incredible accuracy at both high and low speeds | ||||||||||||||||||||||||

|

Leverages a non-contact stereo vision camera to navigate crop rows, allowing you to focus on all other aspects of effective application control. The system helps to minimize crop damage, cover more acres in less time and provide easier machine operations. (VSN Comparison Chart)

| ||||||||||||||||||||||||

|

VSN Full Canopy When crops are too tall to effectively see the row, the Raven VSN Full Canopy solution compliments the VSN system with a non-contact radar sensor that detects stalked crops, such as corn, to keep the machine in between rows. Available through AGCO Parts.

| ||||||||||||||||||||||||

|

Raven AutoTurn Included with the purchase of VSN, automatically performs headland turns without the operator’s input, allowing them to prepare for the next pass | ||||||||||||||||||||||||

|

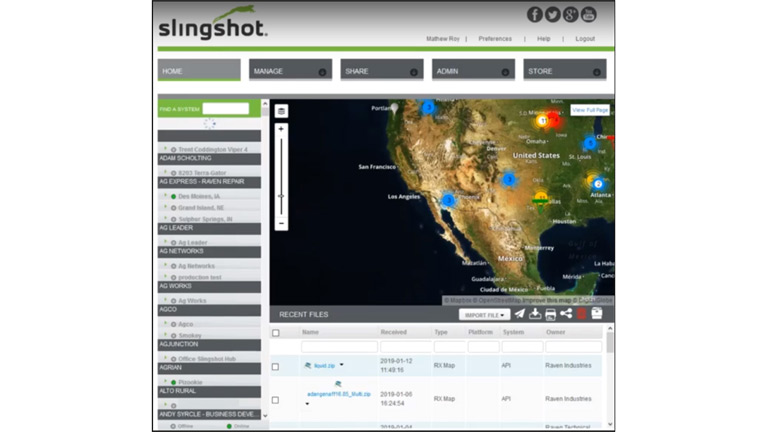

Slingshot Suite of connected hardware, software and logistical services that optimize planning, executing and recording field applications. This system delivers high levels of connectivity to RTK correction signals, online services, sophisticated data management capabilities and live in-field support and service.

| ||||||||||||||||||||||||

|

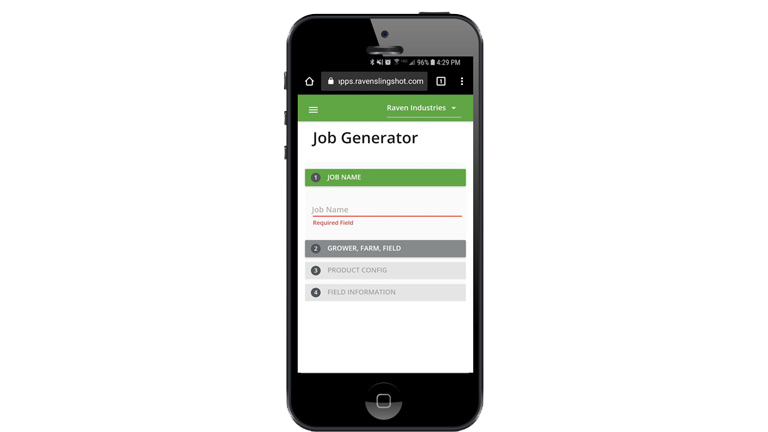

Job Generator

Fast and simple way to set up nearly all parameters of an operation ahead of time and send it out to the machine. | ||||||||||||||||||||||||

|

job Sync Harnesses Slingshot to allow multiple machines to collaborate on a job simultaneously or days apart—a powerful tool that practically eliminates the potential for overlap or misapplication between multiple machines in the same field. | ||||||||||||||||||||||||

|

AgSync Ground Flexible and scalable tool that leverages Slingshot’s data transfer power to streamline otherwise complex tasks, such as work order management, dispatch and asset control, reports and notifications, and filing data management. Weather Station Data: View the latest weather information and record data as a snapshot in time to use it for documentation of the application. | ||||||||||||||||||||||||

|

Data management done right Agro Link relieves you of the data management burden by collecting, integrating and storing agronomic files—so you can focus on more important tasks.

| ||||||||||||||||||||||||

|

Connected performance perfected Take the guesswork out of machine optimization with AGCO Connect. Track individual and fleet performance and know where, how and when you can make the most of your machines.

|