Today's HoursMonday 8:00AM - 5:00PM

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | Closed |

| Sunday | Closed |

Massey Ferguson

Massey Ferguson MF RB4180V Series Round Balers

-

ID # 26649497

- Back ID:26649497

- Book a Demo

- Get Directions

MF RB Series Round BalersThe ultra-efficient Massey Ferguson® RB 4100 Series round baler is built to handle everything your operation demands. Ideally suited for dairy farms or cow/calf operations that need a rugged design to stand up to rigorous baling schedules. The innovative performance features all add up to faster production and the highest quality forage possible. |

|

|

|

|

MORE OPERATOR CONTROL

|

|

|

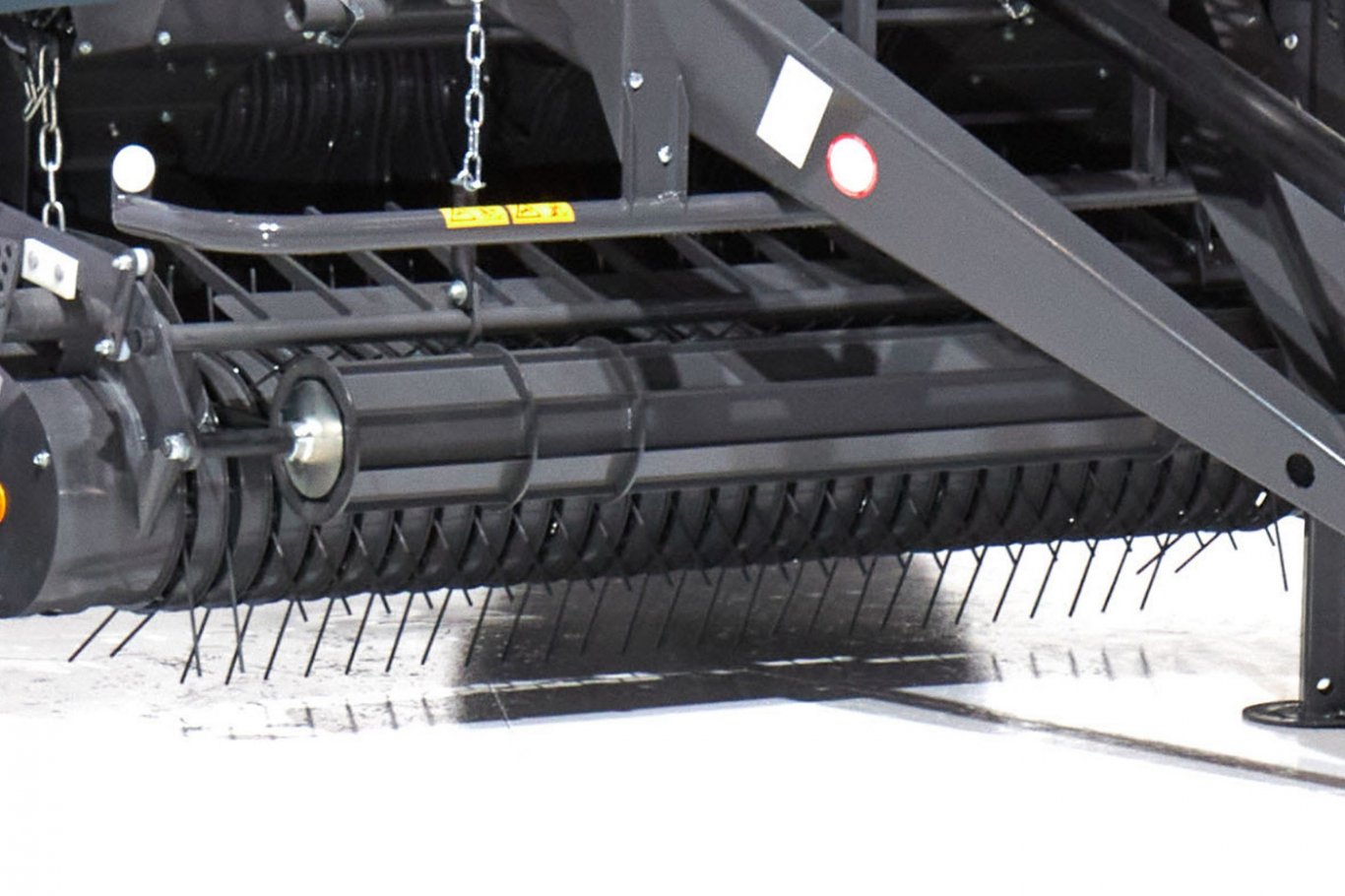

MORE DURABLE TINES |

ANGLED FOR CLEANER PICK-UP |

|

Hydroflexcontrol - Stage 1 |

Hydroflexcontrol - Stage 2Should a major blockage occur, stage two of HydroFlex Control is activated by the operator and is cleared by lowering the rear of the feed table floor hydraulically from the cab, allowing for material to easily pass through. |

|

|

|

|

|

ELS MAKES IT EVEN EASIER |

E-LINK PRO |

MORE VERSATILE PROCESSING

MORE VERSATILE PROCESSING MORE CONSISTANT BALE OUTPUT

MORE CONSISTANT BALE OUTPUT OPTIMIZED OPERATOR PRODUCTIVITY

OPTIMIZED OPERATOR PRODUCTIVITY MORE VERSATILE CUTTING

MORE VERSATILE CUTTING Optional E-Link Pro™ touch-screen monitor tracks bale formation and allows in-cab control of cutter engagement and knife group selection. In addition, the baler’s ISOBUS design allows the use of any compatible tractor monitor for baler monitoring control.

Optional E-Link Pro™ touch-screen monitor tracks bale formation and allows in-cab control of cutter engagement and knife group selection. In addition, the baler’s ISOBUS design allows the use of any compatible tractor monitor for baler monitoring control. MORE TINE BARS

MORE TINE BARS OFFSET TINES

OFFSET TINES MAXIMUM THROUGHPUT

MAXIMUM THROUGHPUT IMPROVED CROP THROUGHPUT

IMPROVED CROP THROUGHPUT HIGHER BALE COMPACTION

HIGHER BALE COMPACTION CAB-CONTROLLED HYDRAULICS

CAB-CONTROLLED HYDRAULICS CONSISTENTLY SIZED BALES

CONSISTENTLY SIZED BALES VARIONET WRAPPING

VARIONET WRAPPING